In the ever-evolving landscape of fluid and gas control industries, the importance of reliable containment shells cannot be overstated. Among the myriad materials available, Zirconia ceramic part emerges as a game-changer, particularly in the domain of wear parts. This article delves into the innovative use of JUNTY‘s Zirconia ceramic in containment shells, exploring its unique properties and the transformative impact it brings to fluid control applications.

Containment Shell: A Breakthrough in Mechanical Seals

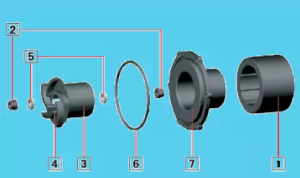

The Containment Shell serves as a pivotal separation component, effectively isolating the external magnet (Drive magnet) connected to the motor from the internal magnet (driven magnet) attached to the impeller. This seal-less solution not only provides reliable leakage-free sealing but also eliminates the risk of mechanical seal failures over time. A notable advantage is the absence of heat generation through magnetic induction, setting it apart from conventional metal counterparts.

Wear Parts Innovation: Zirconia Ceramic for Unmatched Performance

Under the category of Wear Parts, JUNTY’s innovative solution involves utilizing Zirconia ceramic material for the Containment Shell. This material’s unique property of not generating heat in the presence of a changing magnetic field is a game-changer. The result is a reduction in efficiency loss and the prevention of overheating failures, a common concern in various industries.

Modeling Excellence with ANSYS

JUNTY goes a step further in ensuring the robustness of their Containment Shells by employing ANSYS for modeling and stress analysis. This meticulous approach helps identify potential stress points and mitigates the risk of underlying failures, reinforcing the reliability of their mechanical seal components.

JUNTY’s dedication to innovation and precision shines through in the design and application of Containment Shells. These integral components not only enhance efficiency but also contribute to the overall reliability of mechanical seals, making JUNTY a trusted partner in the fluid and gas control industries.